As the UK’s National Metrology Institute, the National Physical Laboratory (NPL) provides the measurement capability that supports the UK’s prosperity and quality of life. NPL is leading the way in providing the measurement science that underpins research and development.

Last year, NPL, in partnership with HM Treasury, hosted a series of Innovation Webinars to showcase some of the exciting innovative science and technology residing in the UK’s public sector and how it could be harnessed to boost UK industry.

One example of ground-breaking innovation showcased was a pioneering digital imaging technique, developed by Dr Nick McCormick, Principal Research Scientist at NPL. One of the most common ways to identify change in objects is to look at them, however the human eye is not good at detecting small changes over time. Scientists at NPL have developed imaging methods in combination with ‘application specific image capture equipment’ (fixed, moving and autonomous robotically carried cameras) to enable automated identification of changes over time, or with use.

Here Dr McCormick explores the journey to developing this innovative new technology:

The quality and maintenance of infrastructure such as bridges and tunnels are informed by inspection. Outside of the factory, most inspection has traditionally been through manual visual inspection - a technique, which is subjective, time consuming, often inaccurate and can put people in hazardous situations. However, this practice is well established and in safety critical infrastructure inspection it is often the only solution that satisfies current safety cases. For ‘in factory’ or ‘as built’, this technique is relatively easy, however, for aged or modified structures such as bridges and tunnels, it is more difficult.

As you can see, manual visual inspection hasn’t changed much over the last 50 years when assessing bridges and tunnels

The NPL’s ‘Spot the Difference’ solution aims to help resolve the issues discussed. The first step is to capture an image for a specific application, which will provide us with baseline data and then the second step is to capture an image of the application at a future date. The two images are then compared to identify any changes, which for maintained infrastructure are - localised and fairly small. We then use business rules to score those changes and then present the highest scoring changes to a trained inspector, ignoring the larger areas where there are no significant changes. The image below helps to show this pixel by pixel comparison of how the ‘Spot the Difference’ technology works. This method has many benefits including; reducing inspection load dramatically, detecting very small changes and moving inspectors out of potentially hazardous situations.

![]()

We can now compare one image against another, block by block at the pixel level, to identify changes

There are alternative techniques like using Machine Learning to identify objects and analyse if those objects have moved or changed. However, this is hard to achieve and even more difficult to write a safety case for. NPL’s ‘Spot the Difference’ is based on augmented manual inspection, which is a well-established technique and works extremely well for very complex environments with small changes, which is the case for most asset inspection scenarios.

Using this method, we have used fixed, moving and robotically carried cameras for various applications including; nuclear waste storage, in rail tunnel examination and civil infrastructure measurement. There are several applications to exploit this technology, one example is security. Using this technique, we’ve been able to identify footprints within a tunnel which even highly trained inspectors were not able to detect.

An example of an autonomous robotically carried camera designed for hazardous pressure vessel internal inspection

We are now developing a portable version of the technology, which will use a smart phones’ camera and embodies much of our experience in capturing and processing images. This approach, using everyday consumer technology, opens up the opportunities for a whole host of new applications, which could include, resolving disputes on car hire damage, goods shipped via auction sites, or damage to houses from rental or construction.

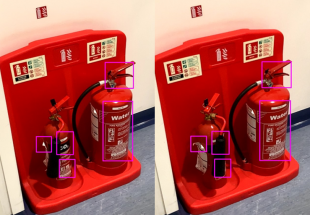

The ‘spot the difference’ technology could be used on smartphones to identify changes, in for example safety related assets. Areas of change are outlined in purple in the “before” and “after” images which highlights the efforts at tampering.

Leave a comment